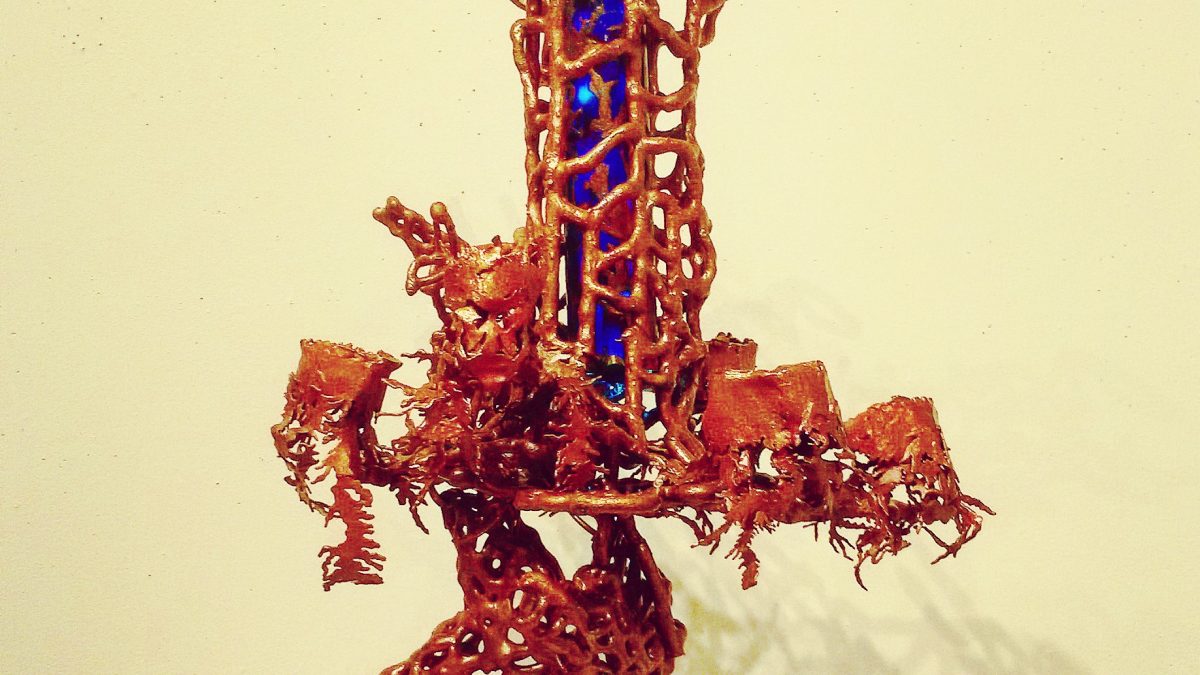

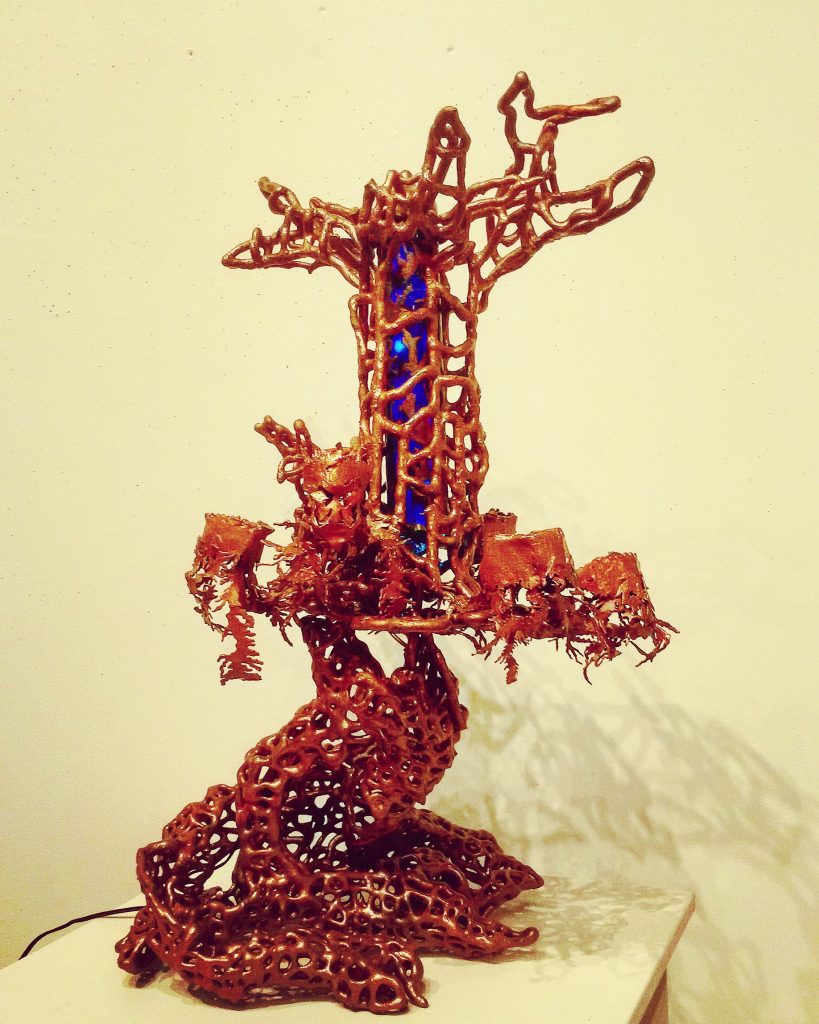

Vital in understanding how to craft materials into useable goods or works of art is to examine our relationships with the raw goods before we reformat them to suit the task at hand. We recently came across a beautiful piece of art that caused us to step back and examine our own relationship with the varying materials that compose the cabinet units reviewed on RTA Cabinet Reviews. From the maple hardwood composing the door frame of the Vanilla Shaker from Best Online Cabinets to the metal side panels of the Simply White Shaker from Kitchen Cabinet Kings, the UV finished interior veneer of the Artisan White Shaker to the rubberwood door of Best Online Cabinet’s White Shaker, a craftspersons relationship with the basic natural composition of materials will determine the relative quality of the project at hand. Whether you consider yourself a tradesperson, an artist, or an individual who falls somewhere in between but simply enjoys working with your hands, the overall quality of your project will be determined by your relationship with the materials. Tradesman and artist Daniel Gilberts provide us with some insight into his own relationship with a variety of materials used in his beautiful piece “Web of Earth” and how his understanding of the materials affected the processes he utilized in bringing his inspired, creative vision to life.

Composed of Borosilicate glass, copper sheeting and rod, and electroformed copper, this incredibly unique and intricate piece dutifully stands balanced upon a mesmerizing and fluid whirlwind of copper roots symbolizing the progression of humanity as culture shifts the dichotomy of our relationship with the natural world. As Gilberts eloquently states in his artist’s statement:

The cohesive design allows for the roots to be, in themselves, a singular component that holds up and supports the large tree (the progression of nature) and a smaller tree (indigenous cultures) and stumps with masks (the established civilizations that have taken over and cut down previous cultures). -Daniel Gilberts, 2018

The resounding themes Gilberts imbeds within this magnificent work of craftsmanship is echoed in his own relationship with the materials composing the Web of Earth. Just as the tradesman-artist maneuvers the glass as he takes it in and out of the kiln, the relationship humanity shares with the natural elements of our world as we fashion them into utilitarian pieces or works of art evolves with our culture. We see this relationship affect the manner in which we produce goods for our homes, treat products we utilize to build furniture and cultivate materials from the planet to build these goods and products.

Gilberts began the process of creating the Web of Earth by scribing the designs for his masks and stumps of the tree into 20 gauge copper sheets. Starting with a sample piece, he sawed and soldered the first free-hand as well as another section to fix onto the front of the stump. In order to accomplish the appearance and texture of tree bark, he sawed several more sections out of the 20 gauge sheets and planished these cuts with both a ball-pen as well as a flat-pen hammer in conjunction the soldering process to create the organic rigidities seen on tree surfaces. Gilberts went on to repeat this process five more times to create a total of six stumps, each representing one of the original six continents occupied by modern human civilization. the repetition of this very detailed and scrupulous process exhibits the balance between consistency in the repetitive cycles of the natural world as well as the inevitable minor changes each cycle experiences as both humanity and the natural world strive to exist in the most ideal circumstances attainable.

“I [then] went through a process of creating five more stumps to represent the six continents that are inhabited by civilization in the modern era. This process was to enhance my ability to create complex multi-part sculptures out of metal and to enhance them with detail and three-dimensional complexity.” -Daniel Giberts, 2018

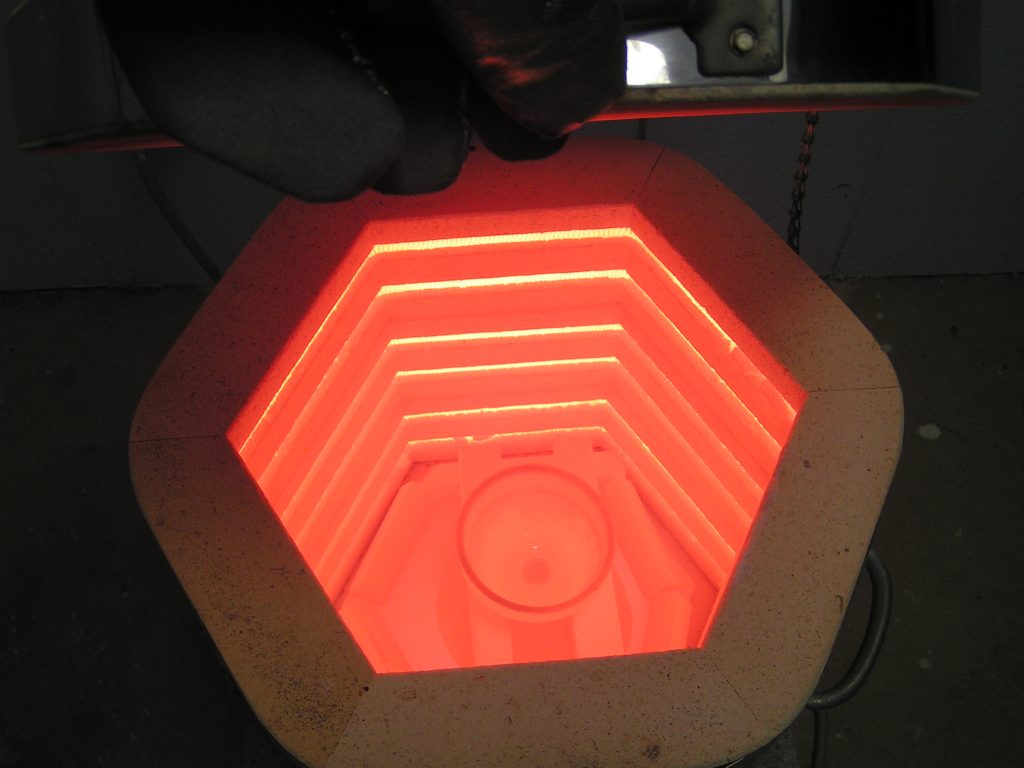

Naturally, the process of forming the glass sculpture was not without its obstacles and challenges. The original structure of the root system was too cumbersome to be completed in a single piece, so Gilberts, with the assistance of another set of hands, added further sections to the main piece and sculpting each of these additions as he placed the structure in and out of the kiln. In order to articulate the root-base that would support the upper echelon of the tree, Gilberts exercised an immense amount of patience in weaving small rods together to the point where they were thick enough to bear the weight and accomplish the balance that would allow the structure to stand on its own. Altogether, he spent 70 hours carefully merging each rod to the main root system. This painstaking, time-consuming process mirrors the one nature takes in constantly adapting and changing in order to meet the needs of survival, as well as how our own relationship with that process changes as we continuously develop new approaches to cultivating and creating art and products.

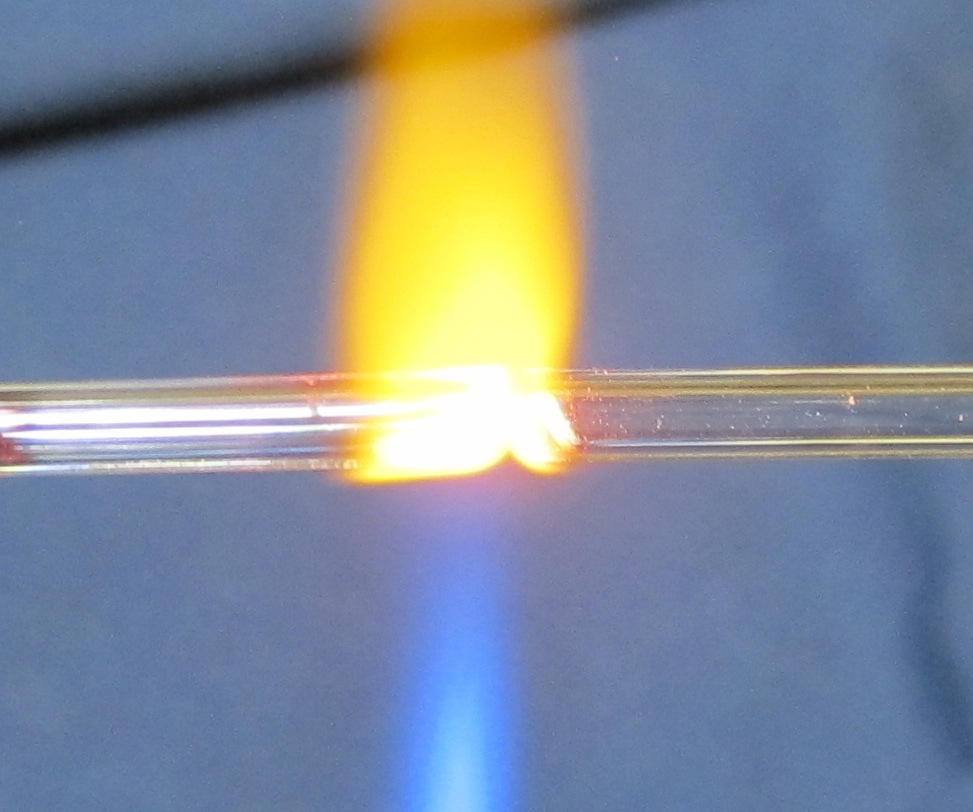

Gilberts next moved into articulating the glass sculpture that would become the main tree and frame. This intricate process included welding glass tubes to one another to form a bridge that he could then maneuver and coax into the desired formations. A knowledge of the exact temperature to keep his torch, the proper amount of time to keep the glass in the flame, the physical aptitude to withstand the heat of the room and keep the glass steady in his hands, and an understanding of the nature of the glass rods and tubes with which he was working was necessary to create the sculpture. After 20 hours and the creation of 30 tree branches, Gilberts astutely determined that the base of the tree would not be able to support the weight of the upper structure and started the process of tying together thin rods over from the beginning. After discovering the new structure was 2 inches larger than the chamber of his kiln, he adapted accordingly and allowed this component of the tree to cool at room temperature while focusing on the welds for posts that would fit into the inner section of the tree and contain the light that would illumine the piece from the trunk. Finally, the time came to attach the upper tree section to the base, which he accomplished using a heat gun set at 150 degrees and consistently moving around the edges of the sculpture until it was securely welded. The only step left after this was to measure the tubing that would contain the center light, cut the top with a flame, and fit the tubes into the posts that would attach them to the base of the tree frame.

Throughout the entirety of the welding process, Gilberts was also dunking the piece in sections to copper plate the entirety of the sculpture. His own description of the process paints a detailed picture of what this task looked like:

“During this the process of making this piece I went through sixteen dunks over the course of two weeks in a homemade copper sulfate solution in order to copper plate the piece. I hand painted a homemade graphite conductive paint onto every surface of the entire piece and dunked the top tree and base and the bottom roots separately. I weaved copper thoroughly through each section several times to ensure conductivity and quickly learned the limitations of the rectifier unit I was using. It was rated for 2.5amps and a minimum of 5 amps should have been used to quickly copper plate the piece. I also found that the copper stumps acted as copper sinks and had to remove them to completely coat the glass. Each time I pulled the piece out, I had to pull all the wire off and then rewire it in select locations to focus on another area. It took 2-3 hours to remove the wire, rewire, and touch up areas with graphite paint which also need to dry in front of a fan between each time. The cobalt center tube was plated in select areas as well.” -Daniel Gilberts, 2018

The final stage in completing the Web of Life for Gilberts was to paint the entirety of the root system, tree truck, mask-stumps, and tree branches. Using painter’s tape to create a stencil and copper paint, he went through every millimeter of the sculpture and taped off the exposed glass until he accomplished rendering the details of the cobalt tubing. As the piece is rather large when both the root system and tree are together, Gilberts allotted himself the option of utilizing copper staples to hold the two pieces of the structure together for display or separating them for safe transportation. With the LED light in place within the trunk of the tree, the magnificence of the Web of Life cannot be understated. It is a balanced, complex weaving of a multitude of earth’s elements that come together to create a unified, cohesive structure that captures the eye and captivates the mind.

We chose to feature Gilbert’s work on our website because it is a perfect capitulation of our goal at RTA Cabinet Reviews: to bring knowledge and awareness to people of the materials utilized in products, goods, crafts, and art. Whether the cabinetmaker will admit it or not, he or she is an artist and conducts a relationship with the materials utilized in articulating a piece. Gilberts’ intricate process in weaving together the Web of Life is a master example of what patience, flexibility, and the drive to create can accomplish when creating a structure that was previously not in existence before skilled human hands combined materials from the Earth to bring a mind’s vision to life. So whether you are an artist looking to bring together various elements to create a work of originality that is expressive and thought-provoking, or a cabinetmaker combining components to build a utility storage compartment that will contain items used on a daily basis around the home, remember to conduct a dialogue with the material with which you are working. Understanding your tools and materials is essential in creating a viable, quality work of art-furniture.

If you are interested in reaching Daniel Gilberts for further questions regarding his piece and the process he took, feel free to leave a comment and we will pass along his contact information.